H0me page history

Golf course evolution

the moment of inertia of the club head, which reduces twisting when the ball is struck off-center, allowing such shots to lose less distance and accuracy when compared with a muscle back iron. More weight is often put into the sole of the club head, which lowers the center of gravity and increases the launch angle of the ball.

The forgiving nature of cavity backs combined with the ease with which they enable the average golfer to get the ball airborne, make them the most popular design of iron with amateurs.

Components

Clubhead

Investment casting, while allowing for a greater range of design options, produces a very stiff and inflexible head that can be difficult to adjust for a player's desired lie and loft. Forged irons, while they allow for easier and a greater range of adjustments are limited in the designs they may be achieved.

The shaft length of an iron decreases as the iron's number increases; therefore the iron number is disproportional to its length. This reduced length means that a clubhead of the same mass traveling at the same angular velocity (degrees per second, as swung by a golfer) has lower momentum because the clubhead's speed is slower. To combat this, higher-numbered iron clubheads are heavier than lower-numbered iron heads; there is generally a 4oz increase in mass between one clubhead and the next higher number.

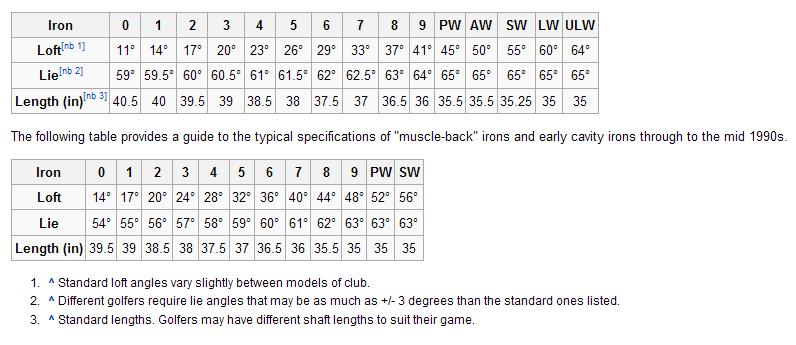

Due to the average golfer's desire to hit the ball farther, the loft on modern irons is much less than that on irons from even the late 20th century. For example a modern 9 iron has comparable loft to a 7 iron from the 1990s. Manufacturers have been able to reduce loft without compromising usability, by moving weight into the sole of the clubhead, thereby lowering the center of gravity and enabling the ball to be launched on a higher trajectory for a given loft than a design with a higher center of mass. Of course, tour professionals now use these same de-lofted clubs, and so the gap in skill and thus in distance between a professional and casual golfer remains.

Over the years, groove technology has changed the playability of irons. For the past 80 years, little has changed about grooves. However, a new rule by the USGA and the R&A has changed the way that grooves are to be made starting in 2010. In general, the deeper the groove, the more grass can be dispersed behind the ball at impact. This allows control over the amount of spin, which is crucial to flight characteristics of the shot as well as how well received the ball is on the green. The less that is between the ball and the club at impact, the more spin that will be produced which increases the flight trajectory and allows stopping quicker upon hitting the green. Better players benefit the most from deep, sharp grooves as the more clubhead speed is generated, the more spin the player is able to introduce. By forcing manufacturers to lessen the depth and cut on the grooves, the new rules will penalize shots from longer grass slightly more and put a premium on hitting the fairway.

Hosel

For irons, the hosel is very noticeable, forming a barrel shape on the inside face of the club and the "heel" of the sole of the club. Many modern irons have a more offset hosel, integrated into the clubhead at a lower point and further from the hitting area of the club. This, combined with the perimeter weighting of modern irons, gives a club with the lowest possible center of gravity and the highest possible usable club face.

A stroke in which the ball comes directly off the hosel is known as a "shank", and the ball will usually veer off almost at right angles to the intended target line.

Shaft

The shaft is the true engine of the iron. A shaft that is perfectly suited to the individual golfer increases distance and improves accuracy, while a poorly suited shaft can lead to inconsistent, wayward shots and reduced distance.

Although graphite shafts, made from composite materials such as carbon fiber, are now standard in woods, especially drivers, shafts for irons are still most often made from steel, which has lower torque than graphite, allowing less club head twisting, which gives better accuracy. Graphite shafts are not uncommon for numbered irons however, as the increased distance conferred by the shaft is advantageous to many players, especially shorter hitters such as ladies and seniors. Wedges virtually always have steel shafts as the accuracy and consistency is of primary importance.

The higher the number of the iron, the shorter its shaft will be, allowing the player a more controlled and consistent swing. The resulting reduction in club head velocity is overcome by an increase in club head mass.

Grip

The grip covers the top of the shaft enabling the golfer to hold the club comfortably. Modern grips are generally made from rubber, sometimes inlaid with cord, but some players still prefer a traditional leather wrap. Even though materials advances have resulted in more durable, longer-lasting soft grips, they still require frequent replacement as they wear, dry out or harden.

By the rules of golf, all iron grips must have a circular cross-section. They may taper from thick to thin along their length (and virtually all do), but are not allowed to have any wasting (a thinner section of the grip surrounded by thicker sections above and below it) or bulges (thicker sections of the grip surrounded by thinner sections). Minor variations in surface texture (such as the natural variation of a "wrap"-style grip) are not counted unless significant.

Types of irons

Numbered irons

Most irons in a player's bag are labeled with a number indicating their loft; the higher the number, the higher the loft. A matched set of irons will have a regular, progressive increase in loft through the irons, which may differ from set to set due to other design considerations that can affect launch angle and distance. Irons have been seen ranging in number from 0 through 10, but the most common number range in the modern iron set is 3 to 9.

Driving Iron

The 1 iron, or driving iron, is the lowest lofted and longest iron, although Wilson did make a 0 iron for John Daly. Often called a butter knife because of its looks, the 1 iron has the least surface area on its face and so is commonly regarded as the hardest club in the bag to hit. The driving iron is virtually obsolete as its nominal range easily falls into that of the easier-to-hit fairway woods, although some sets still include one and it can be purchased separately as a custom club. Lee Trevino is famously quoted, after he had almost been struck by lightning at the 1975 Western Open, that if he were out on the course and it began to storm again he would take out his 1 iron and point it to the sky, "because not even God can hit a 1 iron." By and large, the 1 iron is defunct, and is no longer being produced.

Long irons

The irons from 2 to 4 are typically called the "long irons"; they have the lowest lofts and the longest shafts, and are designed to hit the ball long distances (180-260 yards) with a low launch angle. They are typically used from the fairway or rough, but are also useful in trouble spots such as when "punching out" from underneath a stand of trees.

Long irons are traditionally regarded as the most difficult to hit, because their low loft gives them a very small striking face and "sweet spot" compared to higher-lofted irons. As such, they are less commonly seen in players' bags, usually replaced with higher-lofted fairway woods like the 5 and 7, or with hybrid clubs that have similar overall performance but are easier to hit. The 2-iron, like the driving iron, is virtually never seen in modern sets, due to both its difficulty and to a "de-lofting" of modern cavity-backed irons which increases the average distance of shorter irons. If the long irons are used, they are often seen with graphite shafts to add additional clubhead speed to the average golfer's swing by storing energy from the downswing and releasing it at impact. Hybrid clubs that often replace these irons also often have graphite shafts for a similar reason.

The 5-iron sits on the cusp between "long" and "mid" irons, and can be thought of as belonging to either class depending on the player; it is used more often and replaced with a hybrid less often than the 2-4, but is still commonly replaced with a hybrid club especially in ladies' sets.

Mid irons

The irons from 5 to 7 are typically called the "mid irons", and are generally used from the fairway and rough for longer approach shots between 150-210 yards. They're also used on hillier fairways to avoid hitting a low rise, which is a risk with long irons. These irons are commonly needed for the second shot of a long par-4 or the second or third shot of a par-5, and whenever the player must "lay up" their tee or second shot to avoid a hazard in range of their woods or long irons.

These irons are typically easier to hit well than the long irons, owing to their higher loft which gives the clubs more surface area. These clubs are more often found as true irons in players' bags, meaning they're less often replaced with hybrid clubs or other "iron replacements". These irons often have graphite shafts in newer sets, even when shorter irons have steel; the graphite will give better distance for the average golfer at the cost of some loss of consistency due to shaft torquing.

Iron (golf)

An iron is a type of club used in the sport of golf to propel the ball towards the hole. Irons typically have shorter shafts and smaller club heads than the woods, the head is made of solid iron or steel, and the head's primary feature is a large, flat, angled face, usually scored with grooves. Irons are used in a wide variety of situations, typically from the teeing ground on shorter holes, from the fairway or rough as the player approaches the green, and to extract the ball from hazards, such as bunkers or even shallow water hazards.

Irons are the most common type of club; a standard set of 14 golf clubs will usually contain between 7 and 11 irons, including wedges. Irons are customarily differentiated by a number from 1 to 10 (most commonly 3 to 9) that indicates the relative angle of loft on the clubface, although a set of irons will also vary in club head size, shaft length, and hence lie angle as the loft (and number) increase. Irons with higher loft than the numbered irons are called wedges, which are typically marked with a letter indicating their name, and are used for a variety of "utility" shots requiring short distance and/or a high launch angle.

Design and manufacture

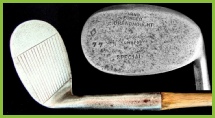

Historically all irons were forged from a flat piece of metal, which produced a thin club head that resembled a blade. Modern investment casting processes enabled manufacturers to easily mass produce clubs with consistent properties. This manufacturing process was first used by PING, and also made it possible to take weight out of the back of the club head and distribute it around the perimeter. These perimeter weighted, or cavity back, irons made it much easier to achieve consistent results even when striking the ball outside the "sweet spot", when compared with traditional bladed, or muscle back, irons.

Although most irons are now produced by investment casting, many high end, particularly muscle back, irons are still produced by forging, as it is believed that the resulting club has an improved "feel". Manufacturers sometimes try to combine the characteristics of both muscle and cavity backed irons, which has resulted in terminology such as cut-muscle, or split-cavity.

There are also many hybrid clubs, so-called because they combine some of the characteristics of irons and woods, that closely resemble standard irons. Indeed, many sets of clubs, especially those marketed for beginners, now include hybrids to replace the more traditional 3 and 4 irons.

Muscle back

A muscle back is the more traditional design and consists of a solid head with little or none of the weight being distributed around the perimeter of the head. As such they require a great deal of skill in order to hit the ball consistently because the "sweetspot" is fairly small. In addition, any shot that is struck "off-center" may be severely compromised in terms of distance and direction.

Perceived advantages of muscle backs are that, when hit correctly, they provide greater distance than cavity backs, and much improved feel, although this is most likely due to the forging process by which they are usually made.

Cavity back

Cavity back, or perimeter weighted, irons are usually made by investment casting. They are so called because of the cavity created by the redistribution of the weight from the middle to the perimeter of the club head when compared with a traditional muscle back.

The perimeter weighting increases the size of the sweet spot and

Golf origins

Long and mid irons

Equipment development

Golf clubs components

Golf woods

Golf putter

Short irons and wedges

Golf balls

Glossary