H0me page history

Golf course evolution

Current graphite shafts weigh considerably less than their steel counterparts (sometimes weighing less than 50 grams (1.8 oz) for a driver shaft), allowing for lighter clubs that can be swung at greater speed.

Beginning in the late 1990s, custom shafts have been integrated into the clubmaking process. These shafts will, within a given flex rating, address specific criteria, such as to launch the ball higher or lower or to adjust for the timing of a player's swing to load and unload the shaft at the correct moments of the swing for maximum power. Whereas in the past each club could come with only one shaft, today's clubheads can be fitted with dozens of different shafts, each with slight variation in behavior, creating the potential for a much better fit for the average golfer.

Grip

The grip of the club is attached to the opposite end of the shaft from the clubhead, and is the part of the club the player holds on to while swinging. Originally, the grip was composed of one or more leather strips wrapped around the shaft. The leather outer wrap on a grip is still seen on some clubs, most commonly putters, but most modern grips are a one-piece "sleeve" made of rubber, synthetic or composite material that is slid over the shaft and secured with an adhesive. These sleeve grips allow clubmakers and golfers to customize the grip's diameter, consistency (softness/firmness) and texturing pattern to best fit the player. Clubs with an outer "wrap" of leather or leather-like synthetic still typically have a "sleeve" form underneath to add diameter to the grip and give it its basic profile.

Grip rules

According to the rules of golf, all club grips must have the same cross-section shape along their entire length (the diameter can vary), and with the exception of the putter, must have a circular cross-section. The putter may have any cross section that is symmetrical along the length of the grip through at least one plane; "shield" profiles with a flat top and curved underside are common. Grips may taper from thick to thin along their length (and virtually all do), but they are not allowed to have any waisting (a thinner section of the grip surrounded by thicker sections above and below it) or bulges (thicker sections of the grip surrounded by thinner sections). Minor variations in surface texture (such as the natural variation of a "wrap"-style grip) are not counted unless significant.

Regripping

Advances in materials have resulted in more durable, longer-lasting soft grips, but nevertheless grips do eventually dry out, harden, or are otherwise damaged and must be replaced. Replacement grips sold as do-it-yourself kits are generally inexpensive and of high quality, although custom grips that are larger, softer, or textured differently from the everyday "wrap"-style grip are generally bought and installed by a clubsmith.

Regripping used to require toxic, flammable solvents to soften and activate the adhesive, and a vise to hold the club steady while the grip was forced on. The newest replacement kits, however, use double-sided tape with a water-activated adhesive that is slippery when first activated, allowing easier installation. Once the adhesive cures, it creates a very strong bond between grip and shaft and the grip is usually impossible to remove without cutting it off.

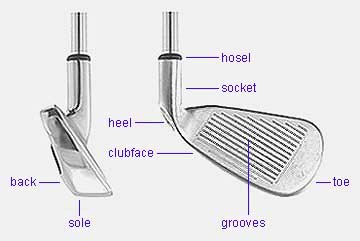

Hosel

The hosel is the portion of the clubhead to which the shaft attaches. Though largely ignored by players, hosel design is integral to the balance, feel and power of a club. Modern hosels are designed to place as little mass as possible over the top of the striking face of the club, which lowers the center of gravity of the club for better distance.

Club head

The Golf Club Head is the bottom part of the Golf Club. The Club head is the Part of the Golf Club that actually hits the ball and they come in various shapes and sizes that all have a great effect on the Golf Ball Flight. Most Golf Club heads are made from wood, steel or titanium. A Golf Club head consists of the following parts:

- Club face

The Club face is the area that hits the ball. Hitting the Ball with other

parts aside from the face makes your ball go to a different direction and not towards

your target. An example of this is the Shank or hitting your ball with the side of

the club thus making the Ball Fly in almost a right angle.

- Toe and Heel

The Heel is the part of the Club head that is attached to the Shaft.

The other end of your Club head is called the Toe.

- Sole

This is the Part of the Club head that rests on the ground. The Sole is designed

depending on the use of your Club. The Driver's Sole is broad and flat making it

glide on the ground.

- Grooves.

The Club face has a set of horizontal Grooves that helps in putting spin

on the ball. Spin makes the ball fly higher and roll less when it lands.

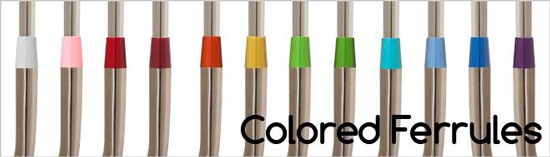

Ferrule

The trim ring, usually black (It may have additional trim colors), that is found directly on top of the hosel on many woods and irons. The ferrule is mostly decorative, creating a continuous line between the shaft and the wider hosel, but in some cases it can form part of the securing mechanism between hosel and shaft. Ferrules of differing weights can fine-tune the center of mass of the overall clubhead, but for these minute adjustments, screw-in weighted inserts at specific points on the clubhead are usually used instead.

Shaft

The shaft is a tapered tube made of metal (usually steel) or carbon fiber composite (referred to as graphite). The shaft is roughly 0.5 inches (13 mm) in diameter near the grip and from 34 to 48 inches (86 to 122 cm) in length. Shafts weigh from 45 to 150 grams (1.6 to 5.3 oz), depending on the material and length.

Shafts are quantified in a number of different ways. The most common is the shaft flex. Simply, the shaft flex is the amount that the shaft will bend when placed under a load. A stiffer shaft will not flex as much, which requires more power to flex and "whip" through the ball properly (which results in higher club speed at impact for more distance), while a more flexible shaft will whip with less power required for better distance on slower swings, but may torque and over-flex if swung with too much power causing the head not to be square at impact, resulting in lower accuracy. Most shaft makers offer a variety of flexes. The most common are: L/W (Lady/Women's), A/I (Soft Regular, Intermediate or Senior), R (Regular), S (Stiff), and X (Tour Stiff, Extra Stiff or Strong). A regular flex shaft is generally appropriate for those with an average head speed (80–94 mph (130–151 km/h)), while an A-Flex (or senior shaft) is for players with a slower swing speed (70–79 mph (110–127 km/h)), and the stiffer shafts, such as S-Flex and X-Flex (Stiff and Extra-Stiff shafts) are reserved only for those players with an above average swinging speed, usually above 100 mph (160 km/h). Some companies also offer a "stiff-regular" or "firm" flex for players whose club speed falls in the upper range of a Regular shaft (90–100 mph (140–160 km/h)), allowing golfers and clubmakers to fine-tune the flex for a stronger amateur-level player.

At impact, the clubhead can twist as a result of torque applied to the shaft, reducing accuracy as the face of the club is not square to the player's stance.

Golf origins

Golf clubs components

Equipment development

Golf set

Golf woods

Long and mid irons

irons

Golf putter

Short irons and wedges

Golf balls

Glossary

The ability of a shaft to twist along its length due to this torque is fundamentally a function of the flex of the shaft itself; a stiffer shaft will also torque less. To counter torque in more flexible shafts, clubmakers design the shafts with varying degrees of torque through their length, particularly along the thinnest part of the shaft where it joins with the clubhead. This results in a point at which the shaft is most flexible, called the "kickpoint"; above that point the increasing diameter of the shaft makes it more rigid, while below that point the shaft is reinforced internally to reduce torquing of the clubhead. Shafts have typically been classified as having a low, medium or high kick; a low kick means the shaft will store energy closer to the clubhead, which means the clubhead can twist more but also allows for higher clubhead speeds. A high kick shaft will store energy closer to the grip; such a shaft will feel firmer when swinging it and will give better control over direction, but the same strength swing will flex the shaft less, which will reduce clubhead speed.

Widely overlooked as a part of the club, the shaft is considered by many to be the engine of the modern clubhead. Shafts range in price from a mere US$4 to over US$1200.